We have already talked here about all those materials and components that make a performance footwear great and innovative. Now we want to complete the picture by taking into account other breakthroughs in the value chain capable of making sports shoes truly innovative.

Table of Contents

SYMPATEX TECHNOLOGIES

The company, a pioneer in the field of sustainable functional fabrics, presents UTMOSPHERIC, a 3D seamless inner ‘sock‘ made of Sympatex membrane in high-performance, environmentally friendly polyester.

Advantages: the elimination of the manual production process of the upper reduces processing time and manual input; material is saved by eliminating the need for tape; the high automation guarantees reliable waterproofing; the breathability of the laminate is doubled; the elastic properties of the membrane and laminate ensure a natural anatomical fit.

NASTROTEX CUFRA

The company has presented the new K-Carbon elastic tape line that exploits one of the fundamental characteristics of carbon, that of controlling the static electricity that naturally accumulates and disperses in the body during prolonged physical exertion and causes negative effects such as muscle contractions, cramps and fatigue.

Elastic tapes with K-Carbon bioceramic yarn therefore offers an overall improvement in performance, as well as having antibacterial and antistatic properties and regulating body heat and moisture.

SÜDWOLLE GROUP

The German Group unveils the new SuperNatural Runner, produced in collaboration with French brand Circle Sportswear: a new running shoe that features a 100% Merino wool lining and a Merino-Tencel blend upper.

The design guarantees high performance, without generating post-consumer waste at the end of the product’s life cycle.

SWISS SHOE SOLUTIONS

Swiss Shoe Solutions offers a comprehensive set of services: concept, service design, market research, product engineering and development, material toolbox, go-to-market, sourcing, quality control, GRS, compliance.

The production of moulds made with 3D Printing has many advantages, both in the design and manufacture of the mould itself.

It has no design limitations, even with curved surfaces, and allows 3D textures directly in the mould. The process is more sustainable because it does not use chemicals and uses 40% less energy. The moulds are ready in just two weeks and are lighter.

ZERO1

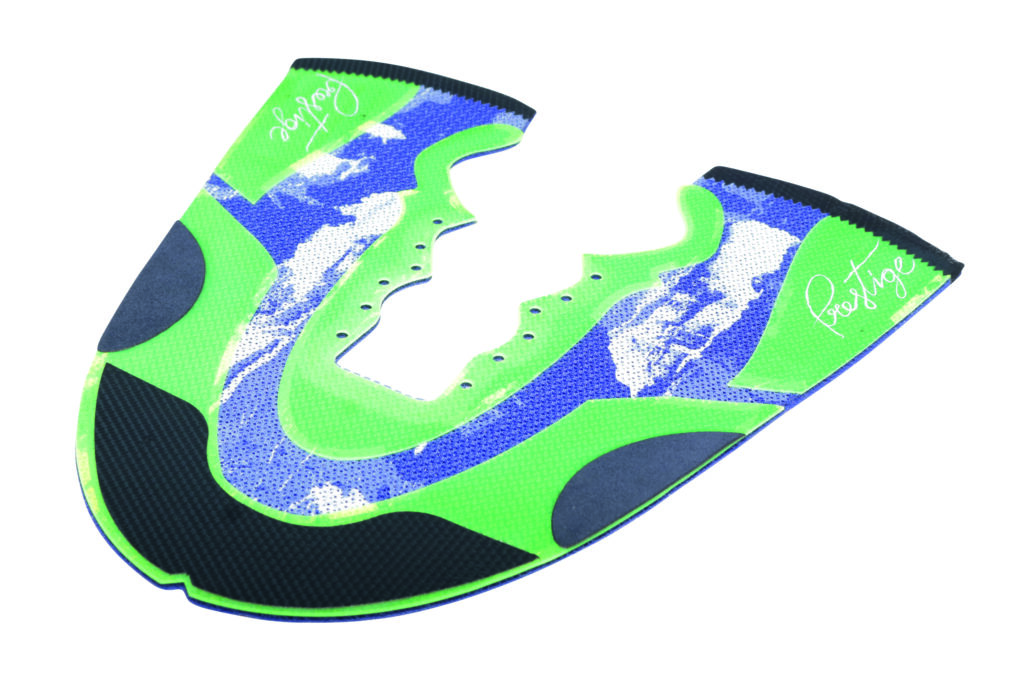

Founded in 2016, Zero1 is the merger of two entities that work symbiotically: on the one hand, the Print Lab section, specialising in innovative garment printing and customisation, and on the other hand, the Clothing Division, specialising in the design and production of technical clothing.

The company’s goal is to provide a quality service in the production of high-end garments for third parties by offering: screen printing, high resolution digital printing, transfer, laser cutting & BOND-IN.

Why can such a company be innovative? Because the mix of skills accumulated in various sectors can bring out of the ordinary ideas to the world of footwear uppers.

You may also be interested in the following articles:

The return of peep toe shoes and the trend of the moment

From heels to open-toe boots: The 2024 trend, inspired by Victoria Beckham

Italian luxury brand Golden Goose and its Haus of Dreamers

Discover Golden Goose’s opening of Haus of Dreamers and the triumphant debut at Paris Fashion Week

When a Color Sets the Fashion: The White Shoes Trend

From the tennis courts to the hottest catwalks of the moment. White shoes have become a must-have for any occasion!